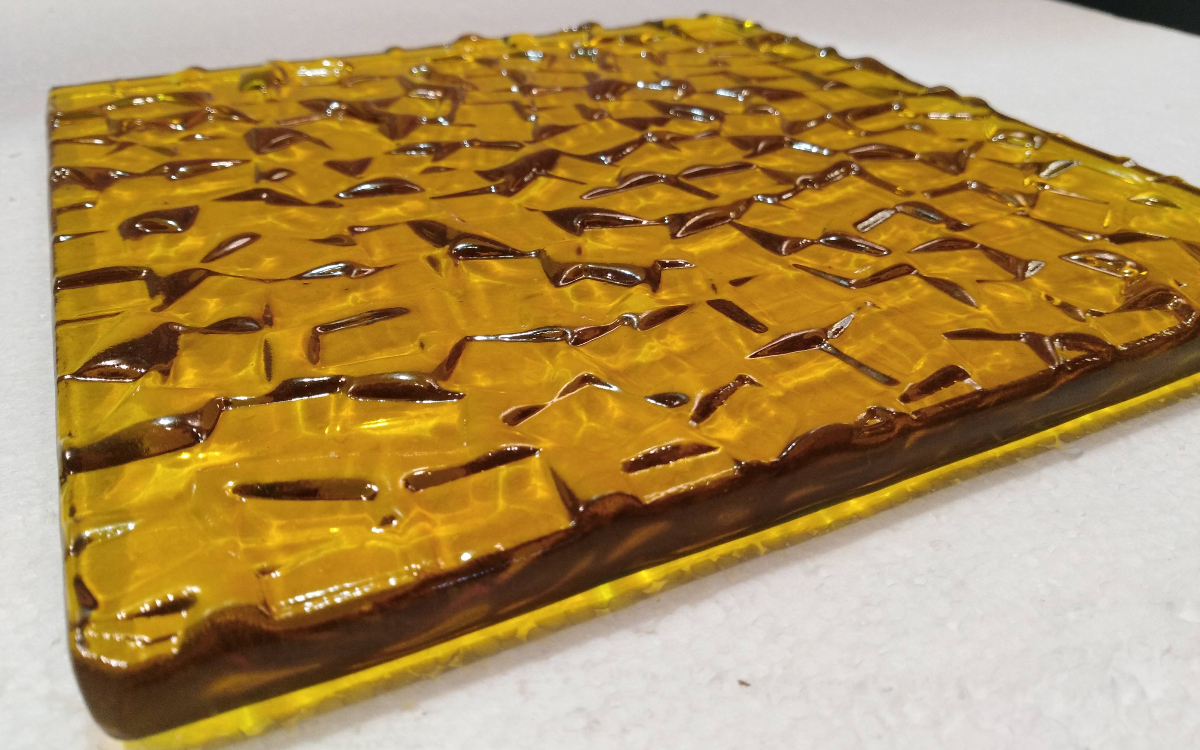

The material of fused glass is float glass. The thickness of glass depends on the shape and requirement of the product. But the glass must be cleaned and dried again. If there are oil stains and dirt, it will be displayed on the surface of the glass after hot working. The tin surface of the glass must be down to determine which side of the glass is tin surface. The tin surface detector can also be used to observe the cut section. Experience to judge.

The main equipment of fused glass is hot melting furnace, which is heated by box electric heating. Infrared electric heat pipe is installed on the upper part of the furnace as heating element. The flat glass placed in the furnace is heated mainly by radiation heating. Infrared electric heat pipe makes the temperature distribution in the furnace more uniform than resistance wire heating. The temperature system in the furnace is controlled by digital temperature control box. According to the specified heating curve and heat preservation, annealing is carried out according to the annealing temperature system. The heat treatment temperature is determined according to the variety, thickness and processing pattern of the glass. It must be 785 degrees above the softening point of the glass, 770 degrees above the green float glass, and the holding time is about 2.5 hours.