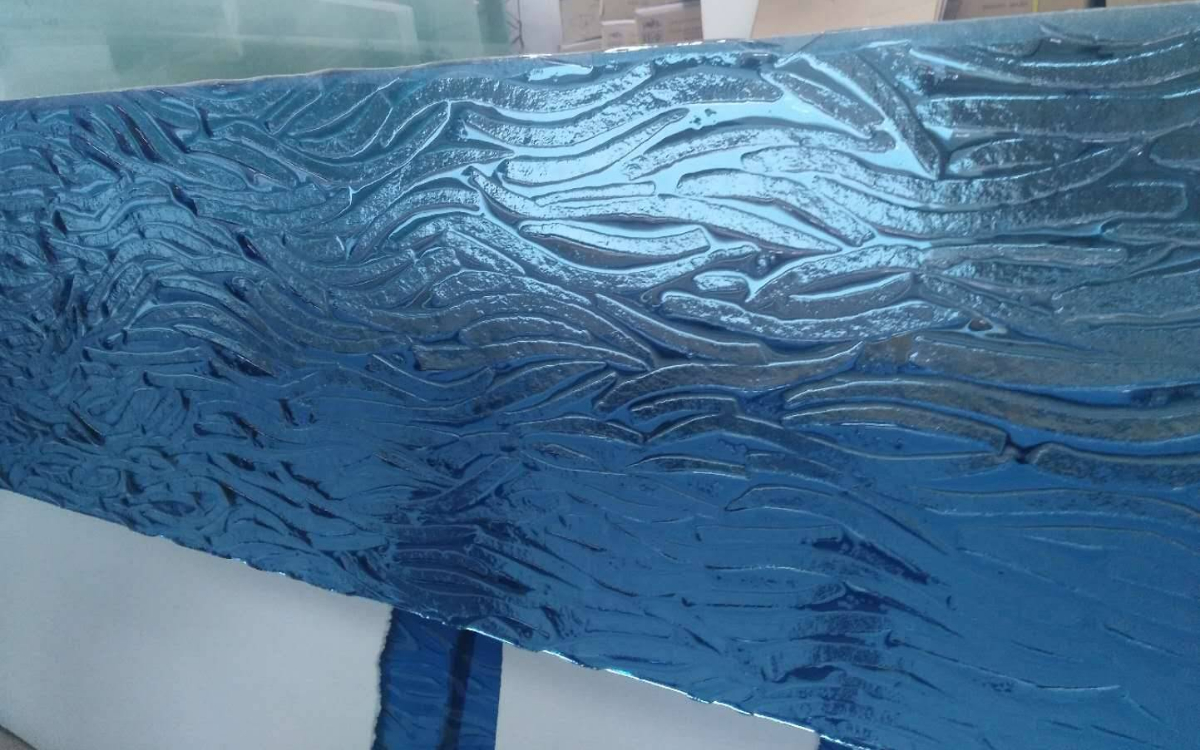

Laminated glass is a kind of decorative fused glass formed by many wavy glass strips heated by a hot melting furnace and naturally bonded together. Ice peak and moire shape glass are basically the same, but ice peaks are like peaks. The wave height of laminated glass is generally about 2.6 cm (in this case, 5mm glass, the thicker glass is appropriately enlarged). The lower part is as flat as the stripe. The distance between the height and the height depends on the size of the whole laminated pattern. The length of the wave is longer. Flat side is generally about 1.3 cm, discharge glass should be placed on both sides of one or two more flat strips, the middle of one or two flat strips and one or two waves at intervals. Before putting the glass, the bottom of the furnace should be leveled, and a warm paper or plain paper should be laid on it. Pay attention to squeeze the glass as far as possible, in order to prevent the burning is not strong, around or on both sides with the mold bar to block, in order to prevent the bar falling down and the size of the burnt.

Processing glass without mould requires 3 points.

(1) Because each glass manufacturer produces a glass with a different melting temperature, it is very easy to burst during the hot melting process because of its different coefficient of thermal expansion. So we must use the same batch of glass produced by the same manufacturer, one side is cut into a straight face, one side is cut into a wavy shape, or both sides are cut into a wavy shape, the specific operation according to actual needs and requirements.

(2) Glue the cut glass strip with no shadow adhesive or 502, no large area of glue, as long as you can glue the glass strip. If the laminated glass is not large, it can be bonded before putting into the hot melting furnace. If the glass is relatively large, it can be directly bonded or partially bonded in the hot melting furnace after splicing.

(3) the process is mainly controlled by a hot melting furnace. The intrinsic reason of glass self-explosion is that nickel sulfide impurities are mixed into the glass manufacturing process. Nickel sulfide crystallizes in two ways: alpha phase at high temperature and beta phase at low temperature. During annealing, if the temperature drops too fast, the alpha phase will not change into a beta phase, and the glass will self burst. The temperature dependence of nickel sulfide is very large, when the temperature is 280 degrees, the transition time is only 1 hour, and when the temperature is 250 degrees, it takes 100 hours, so temperature control is very important. Some glass has not been transformed through a few small progress, but it has no effect.

(4) The glass and temperature are strictly controlled by the peak and folding pattern of ice-firing, and the glass is required to be used well. The temperature control depends on the different stoves. If the quality of the glass is not in good condition or the temperature is not well controlled, it is possible to burst the burned product. Therefore, we must constantly accumulate experience before we can burn better products. The burning pattern and the ice peak can not be forced to cool down. It is necessary to drop to normal temperature before blowing out.