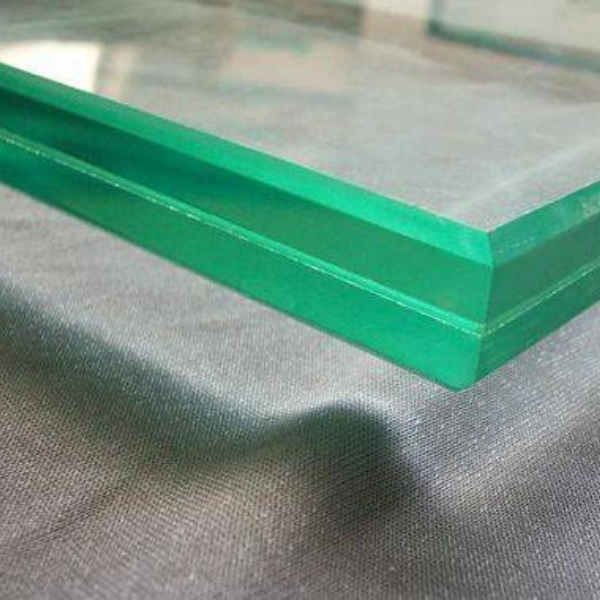

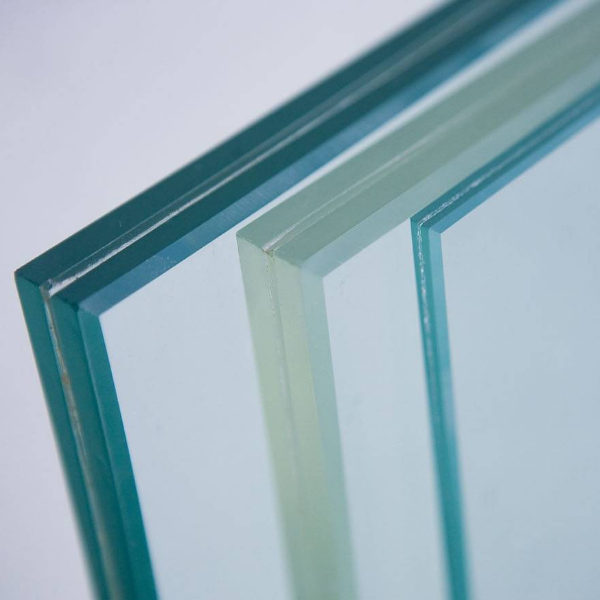

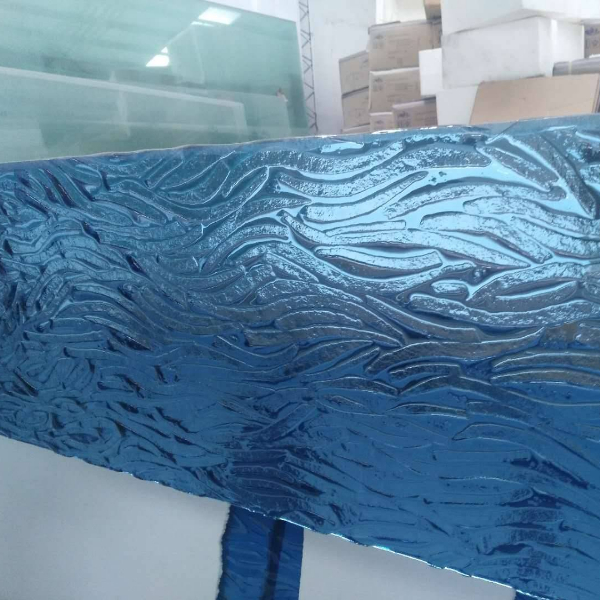

Laminated glass is a kind of decorative fused glass formed by many wavy glass strips heated by a hot melting furnace and naturally bonded together. Ice peak and moire shape glass are basically the same, but ice peaks are like peaks. The wave height of laminated glass is generally about 2.6 cm (in this case, 5mm glass, the thicker glass is appropriately enlarged). The lower part is as flat as the stripe. The distance between the height and the height depends on the size of the whole laminated pattern. The length of the wave is longer. Flat side is generally about 1.3 cm, discharge glass should be placed on both sides of one or two more flat strips, the middle of one or two flat strips and one or two waves at intervals. Before putting the glass, the bottom of the furnace should be leveled, and a warm paper or plain paper should be laid on it. Pay attention to squeeze the glass as far as possible, in order to prevent the burning is not strong, around or on both sides with the mold bar to block, in order to prevent the bar falling down and the size of the burnt.